Benefits

Unmatched benefits to help supply chain logistics operate efficiently as never before.

Compact Containers Provides Cost ESG Storage Functional Benefits

Learn about the transformative impact of our SeaFold 40′ collapsible containers within the logistics and maritime sectors. With unparalleled cost-efficiency, environmental benefits assessed by a 3rd Party ESG firm, and operational advantages, these innovative containers are revolutionizing how businesses manage storage and transportation.

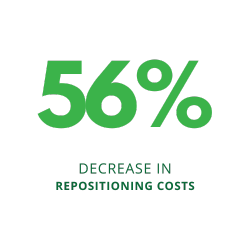

Cost-Efficiency

Owners and operators stand to benefit from substantial cost savings with the SeaFold 40′. Operators can expect to see up to a 56% decrease in repositioning costs with SeaFold containers compared to a conventional 40’ High Cube.

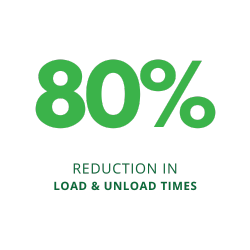

A collapsed bundle of five SEAFOLD containers accommodates the same slot as one conventional 40’ High Cube container, creating 80% more storage and operating efficiencies at terminals, railheads, and ports along with reducing container lifts and container movements on ships, trucks, rail, and barges.

On mainline and feeder vessels, Seafold’s efficient 5:1 design means significant cost savings for one-way cargo shipments through the creating of additional storage spaces, more efficient loading and unloading, reduced repositioning moves, reduced vessel port time, and reduced number of crane cycles when lifting bundled units.

At container terminals, railheads, and ports, SEAFOLD’s compact nature when collapsed translates to lower storage and transportation costs, alleviates current and future port congestion, helps prevent future container shortages and surpluses. Additionally, the efficient design means quicker throughput times at ports, thereby reducing associated logistical costs with numerous lifts.

On inland transportation, SEAFOLD’s 5:1 profile and impressive technical abilities means multiple SEAFOLD containers can be collapsed and bundled onto a single truck or rail chassis. On a double stack train, up to ten (10) SEAFOLD containers can be bundled on a rail chassis equated to immense cost savings. SEAFOLD usage reduces empty container repositioning and improves rail and truck storage.

Approximately 20% of all ISO Containers moved worldwide are empty and consume valuable space on ships, trucks, trains, inland barges as well as vast amounts of prime real estate at ports, terminals, and depots. Movement of empty conventional containers consumers millions of hours of truck, tractor chassis, and railcar capacity each year, as well as millions of tons of marine and diesel fuel.

The SeaFold 40’, with its revolutionary 5:1 profile, has the potential to provide a dramatic reduction in costs associated storage and operating cost efficiencies at terminals, railheads, and ports along with a drop in lifts and container movement on ships, trucks, rail, and barges, as well as a dramatic reduction in carbon emissions and energy output.

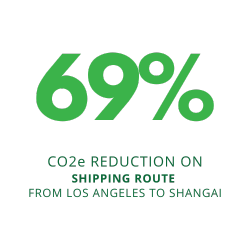

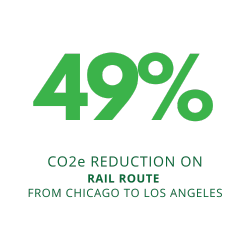

Reduced Carbon Footprint

The SeaFold 40′ container introduces a new era of environmental responsibility in the maritime logistics sector. Its 5:1 profile significantly decreases greenhouse gas emissions, especially during return journeys, quickly becoming a cornerstone for efficient supply chain resource management. This emission reduction is underscored across several transportation modes and boundary levels, which was meticulously examined through various routes and levels of analysis: Ship, Rail, Truck, and Barge.

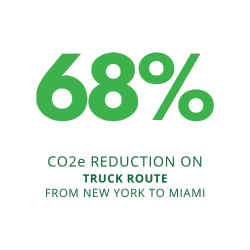

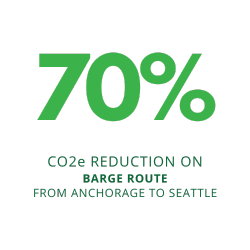

Testing performed by a third-party ESG analytics firm found that, when compared to transportation of empty conventional 40’ High Cube containers, five collapsed SeaFold containers in one 40 ft High Cube slot achieved a 69% reduction in metric tons of CO2e emissions on a shipping route from Los Angeles to Shanghai, a distance of 6,000 miles, a 49% reduction in emissions on a rail route from Chicago to Los Angeles, a distance of 2,000 miles, a 68% reduction on a truck route equidistant from New York to Miami, a distance of 1,300 miles, and a 70% reduction on a barge route from Anchorage to Seattle, a distance of 1,400 miles.

| DESIGN BENEFITS | OPERATING BENEFITS | TECHNICAL BENEFITS | ESG BENEFITS |

|---|---|---|---|

|

5:1 Design Ratio Creates 4 revenue generating slots Fully ISO 1496-1-2013 and 668 Certified Meets all CSC, UIC, Lloyd’s Register, and Bureau Veritas standards |

Creates operating efficiencies at terminals and ports Streamlines empty container repositioning Provides significant cost savings for maintaining container fleets Prevents containers shortages and surpluses Few stranded/idle containers Faster throughput of containers Increased operating flexibility Container load/unload time reduced by 80% Container storage space reduced by 80% Reduces operational costs |

Utilizes existing intermodal equipment and interconnects Constructed from the highest quality industry standard materials Compatible with all current ISO container equipment Easy & safe folding procedure Quickly collapsed or erected in minutes Matches existing container external dimensions Seamless maintenance, repair, and overhaul |

Sustainable solution across intermodal supply chain

Helps satisfy CO2e emission requirements Decreases greenhouse gas emissions, especially on return journeys CO2e Reduction across all modes of intermodal transportation More efficient and greener handling workflow Cuts down carbon emissions associated with port and terminal vehicles and machinery |